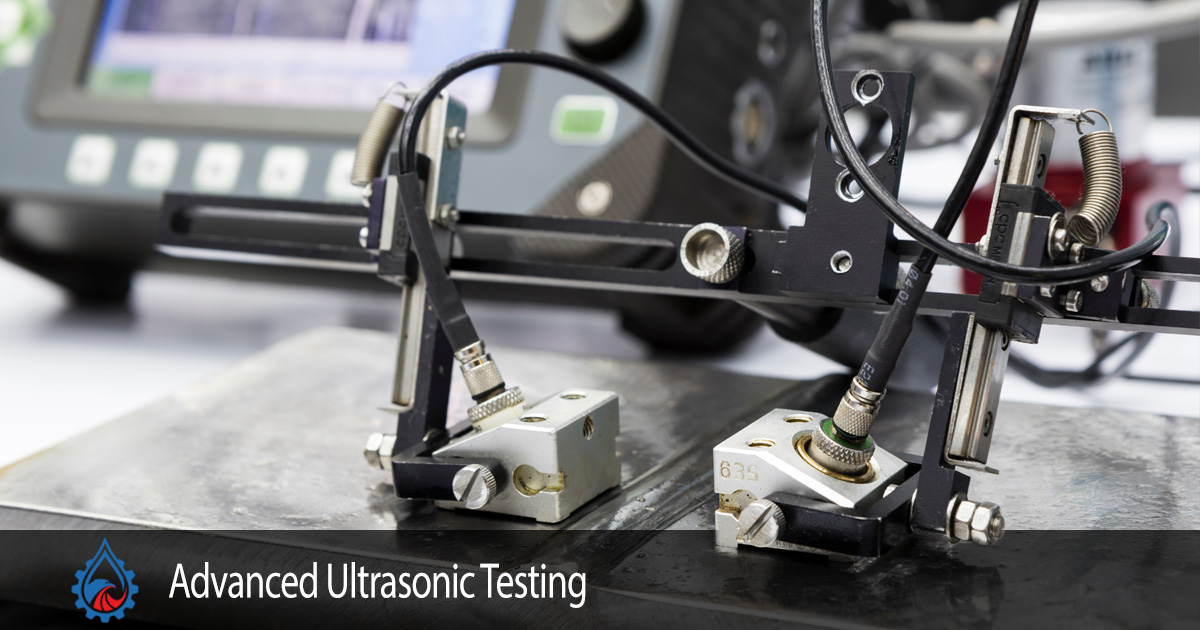

As technology constantly evolves in our world, so too do the options available for nondestructive testing. Advanced ultrasonic testing provides faster and more accurate testing technology.

Advanced ultrasonic techniques consist of applications that utilize longitudinal waves, shear waves, and sometimes surface waves with hardware/software integrations which allow for greater control of these waveforms. The ability to control the characteristics of ultrasonic energy increases accuracy and the techniques available.

Types of Advanced Ultrasonic Testing

USINDT performs a wide array of ultrasonic testing techniques that include conventional means of examination with manual techniques as well as advanced systems that employ automated acquisition and software aided analysis. The most common of the advanced ultrasonic techniques used are Phased Array (PAUT), Time of Flight Diffraction (TOFD), and Automated Corrosion Mapping.

Shear Wave Testing

Phased Array Ultrasonic Testing (PAUT)

Phased Array Ultrasonic Testing (PAUT) uses multiple ultrasonic elements and electronic time delays to generate and receive ultrasound. Therefore, PAUT offers significant technical advantages over the conventional single-probe approach. The most significant of these advantages are that phased array beams can be steered, scanned, swept, and focused electronically.

PAUT is a very flexible technology that is used in a wide variety of industries, including aerospace, power generation, steel and pipe mills, petrochemical plants, pipeline construction, oil and gas, and special applications. Typical applications of PAUT are determining quality of materials, detecting discontinuities in welding operations, detecting cracks on in-service components, and monitoring overall condition of in-service assets.

Time of Flight Diffraction (TOFD)

Time of Flight Diffraction is an ultrasonic technique that can provide improved detection and sizing capabilities of discontinuities in comparison to standard pulse-echo techniques. TOFD uses the time difference between tip diffraction signals from discontinuities for a more accurate sizing technique. Additionally, because TOFD is dependent on diffraction instead of reflection, it is more suitable to detect discontinuities that are randomly oriented.

The TOFD technique is typically used as a supplementary method for weld inspection. It is usually used in conjunction with other weld examination techniques like PAUT to increase probability of detection and accuracy sizing. Applications for this technology are very similar to PAUT, however, it can be very beneficial in crack detection and sizing as well as detection of nonplanar discontinuities.

Corrosion Mapping/C-Scan Inspection

Automated corrosion mapping systems use a flaw detector paired with analysis software to acquire and analyze data to determine the overall condition of components. They are especially useful in determining remaining thickness and possible degradation of materials from chemical or electrochemical issues. It can be used to detect corrosion along grain, uniform corrosion across the surface, or pitting.

This technique is widely used in the oil and gas industries to inspect pipes, pressure vessels, storage tanks and reactors. It can also be used to scan composite materials in the aerospace industry.

Benefits of Advanced Ultrasonic Testing

Advanced ultrasonic testing offers many benefits over conventional testing, primarily speed and accuracy.Since larger areas can be tested with less movement, inspection is faster than technologies which require scanning with multiple fixed angle probes. Sometimes tests can be completed in only seconds, providing our experts with all of the data they need. This data can be evaluated away from the testing site, resulting in less interruption to work in the area.

Ultrasonics also provide much more accurate results, especially when testing areas with complex geometry. It increases the chance of finding defects before they can cause a failure and makes it easier to pinpoint those defects for repair.

Costs of Not Testing

Avoidable Equipment Damage

Danger to Workers and Others

In many cases pipes and tubes carry toxic materials or operate under high pressure. In these cases, a failure could cause serious injury or death for anyone in the area when it happens. Any leak in a pipe carrying a tox material could release threats to nearby residents and possibly open you up to fines and legal action.

It’s much less costly to perform regular maintenance and testing than to deal with the aftermath of an avoidable failure.