The recent arctic blast that brought ice, snow and sub-freezing temperatures to areas that don’t normally experience them, put historic pressure on the power generation sector. The strain, which caused power outages and rolling blackouts for many customers, illustrates the importance of keeping facilities in good shape and running at top capacity.

A huge asset in ensuring that the power grid doesn’t fail is a regular schedule of maintenance that includes power plant inspection and nondestructive testing.

Benefits of power plant inspection and nondestructive testing

Existing structures

New construction

It’s also important to use power plant inspection and nondestructive testing methods during construction. Anything that is being welded in a construction situation must have sound metal thickness, and radiography or ultrasonic testing are the best methods for verifying that. All piping systems, boilers or anything that requires welding should be inspected to verify integrity so that no one’s life is in danger when that plant is put online.

We can also help with refurbishments or enhancements to existing power plants.

Costs of not testing

Looking at it through the lens of the recent arctic blast and the added demand, when something fails in a power generation plant, that failure can shut down the whole plant and its ability to generate power. A failure of that magnitude can leave customers in the dark and in danger.

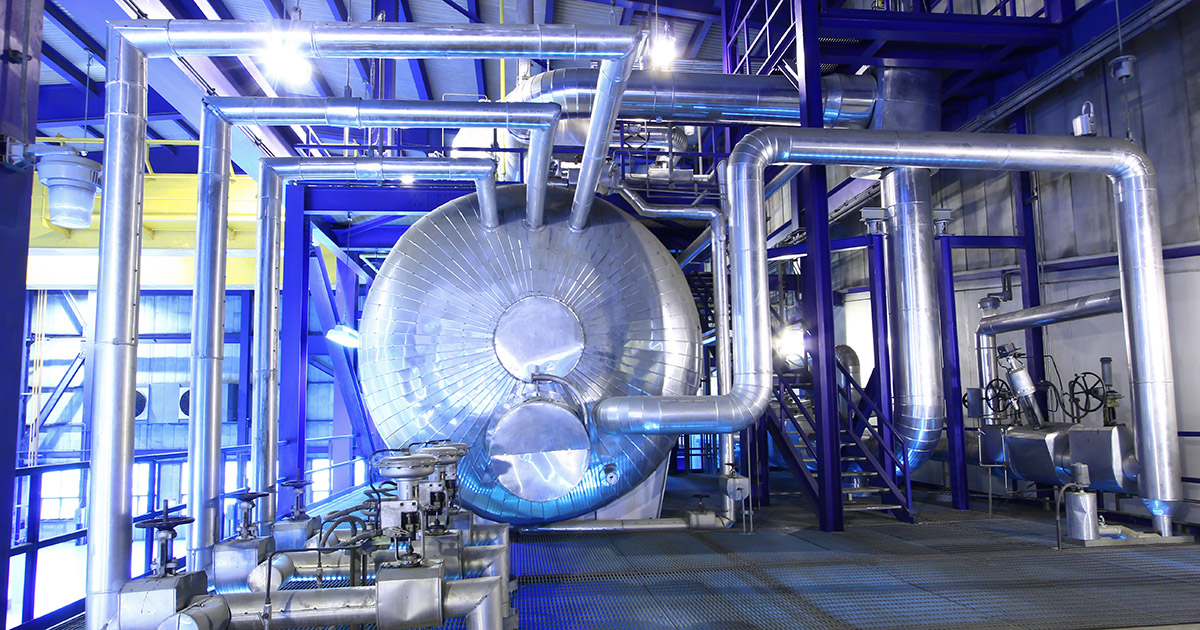

To understand the dangers, you must understand how power generators work. The boiler serves as a combustion chamber. Coal, oil or another fuel source burns in the boiler and in turn heats water that runs through tubing. This produces steam, which is what eventually becomes electricity.

Equipment damage

Danger to workers and others

There’s also a very real danger to workers and others. These tubes carry superheated water, and if a line blows out, it will most likely cause serious injury or death for anyone in the area of the accident. It’s even worse in some applications, such as chemical plants, in which case you also have to worry about what might be released into the air and the threat to nearby residents.

It’s much less costly to perform regular maintenance and testing than to deal with the aftermath of not doing it.

What kind of equipment should be tested?

Power generators are not only found in the plants that provide electricity to our homes and businesses. While those need inspection and maintenance to keep the grid up and running, there are other types of generators that should have power plant inspection and nondestructive testing to ensure their integrity.

Large ships, for example, have power boilers that operate in the same way, just on a different scale. Other good examples are paper mills or chemical plants, which both have some kind of boiler unit for power generation. These must be shut down, typically on an annual cycle, for inspection.

Once the boiler in a mill or plant is shut down and cleaned, inspectors go in to inspect the bare metal tubes and walls of the boiler for defects. These are normally in the middle of a structure in almost complete darkness. In this case, we take advantage of that darkness and use a fluorescent penetrant, which is much more sensitive than other types and makes it easier to spot any potential problems.